Following the functional assessment and prescription with your prosthetist and care team and once granted funding approval, we can start the manufacture process of your prosthetic leg.

The process will vary for everyone (eg number of appointments needed, number of check sockets) but below is a basic outline of the steps to get your leg prosthesis.

Following the functional assessment and prescription with your prosthetist and care team and once granted funding approval, we can start the manufacture process of your prosthetic leg.

The process will vary for everyone (eg number of appointments needed, number of check sockets) but below is a basic outline of the steps to get your leg prosthesis.

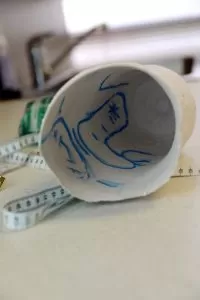

1. Measure & size for liner

2. Cast: The shape of your residual limb is captured via plaster cast or scan

Casting Process

3. Cast modifications: Behind the scenes, your prosthetist will fill the negative cast with plaster and then the positive mould of your residual limb is modified (or modified on the computer if a scan was taken)

Casting modifications

4. Check socket fabrication: Plastic is draped over the positive cast by the technician and aligned to the componentry. For a more detailed look at the materials are commonly used in prosthetics, you can find further information here.

Check socket fabrication

5. Check socket fitting: Trial fitting with your prosthetist where height, alignment, fit, pressure distribution and comfort are all assessed before you take it home to try in in the real world!

6. Review: It’s important to give feedback to your prosthetist (good and bad- especially bad!) so we can make changes and ensure you have the most comfortable, well suspending socket, that has the optimal alignment. Communication is key!

7. Definitive socket fabrication: The prosthetist or technician duplicate this to manufacture the definitive socket. You may have this anywhere from 6 months to 3 years depending on time since amputation and stability of your residual limb volume.

Definitive socket fabrication

8. Definitive socket fitting: This fitting hopefully goes smoothly – When we work as a team – with you giving great feedback on fit and function in the earlier appointments, and your prosthetist listening to you making those changes, you should walk away with a lightweight, durable carbon prosthetic leg that meets your needs.

9. Reviews: regular reviews are recommended to maintain fit and function, to inspect for wear and tear and ensure the device is still meeting your goals.

If you are a new lower limb amputee (undergone a recent leg amputation) and would like to know more about how the process of getting your first prosthesis works.